Why Pressure Forming?

Pressure forming offers quality and detail that can match or exceed other plastic manufacturing processes, with lower tooling costs and better lead times. All of this is backed by our obsession with precision and quality – that’s the Ray Products Advantage.

Utilizing cutting-edge equipment and the latest technology, Ray Products manufactures custom plastic parts using an advanced, heavy-gauge pressure-forming process to deliver the highest quality and repeatability in the business.

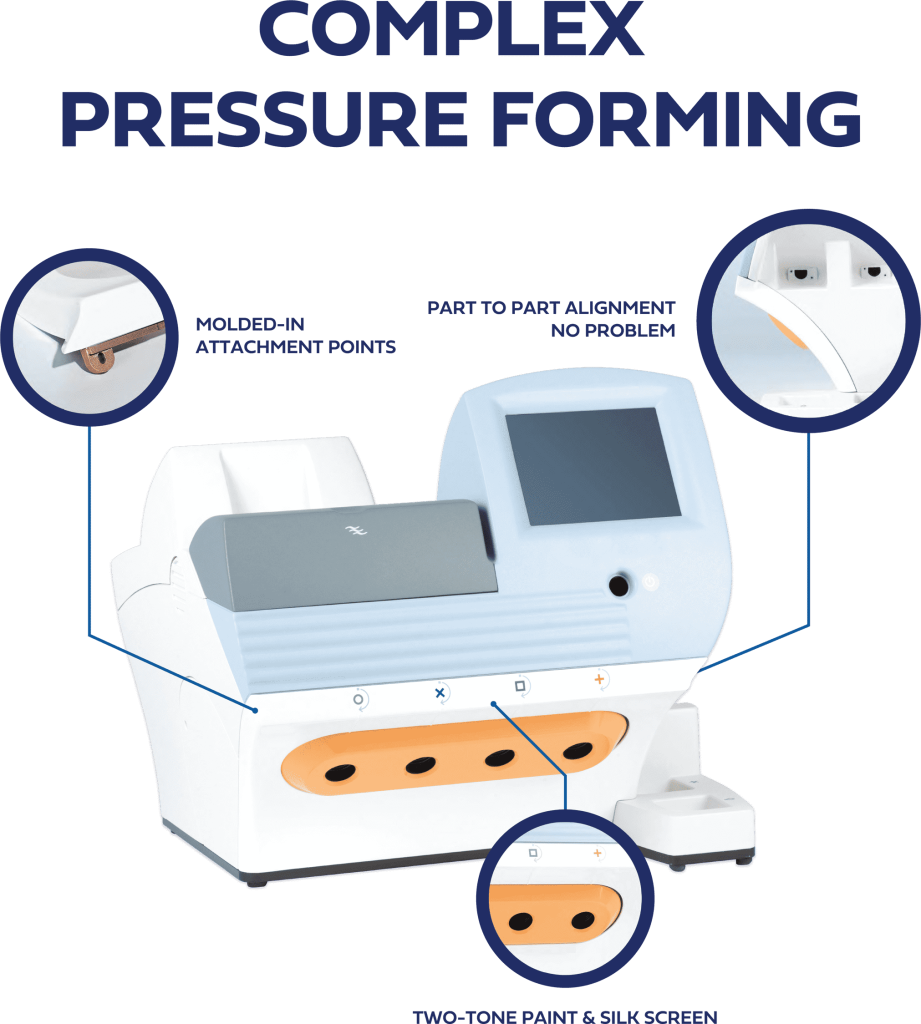

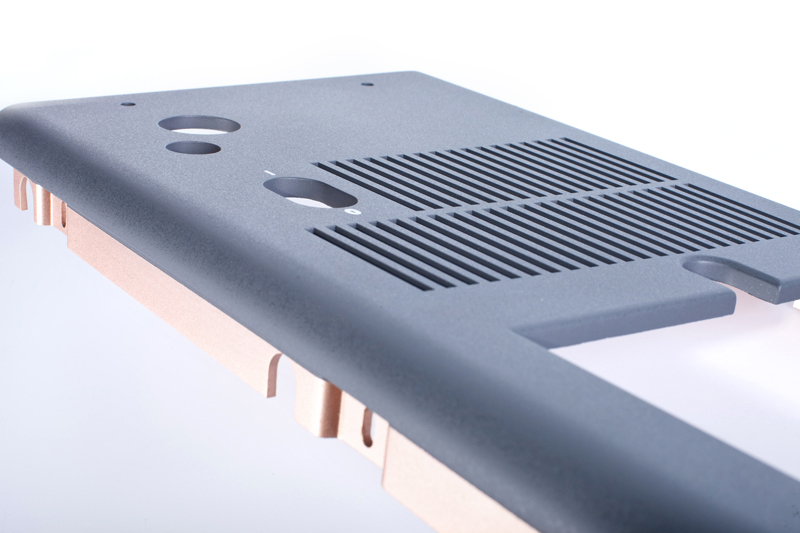

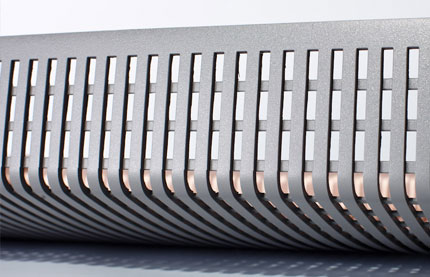

Pressure forming creates highly detailed plastic parts in a process where heated thermoplastic sheets are pressed against their mold surface using both vacuum and pressure. The result is plastic parts with zero residual stress, a high level of detail, and molded-in features like vents and louvers, textures, letters and logos, sharp corners, tight tolerances, and zero draft.

With the ability to form in undercuts and snap-fit features, pressure forming can reduce assembly time while providing similar cosmetic qualities typically seen with injection molding, with a high-quality finish that doesn’t need to be painted.

Think that Injection Molding is the only option for custom plastic manufacturing? Think again.

With affordable tooling and production costs, pressure forming is often the best option for production runs from low to mid-volume. At Ray Products, we can pressure form large plastic parts up to a full 6′ x 10′, with up to 36” of depth and starting sheet thickness from .060″ up to .500”.

The Advantages of Pressure Forming

- High Levels of Detail and Precision

- Attractive Cost at Quantity

- Large Part Capability

- Complex Geometry Without High Costs

- Part-to-Part Repeatability

- Molded-In-Color, Textures, Lettering & Logos

- Molded-In Undercuts, and Snap Fit Features

- Flexible Finishing Options

- Several Thermoplastic Material Options exist that meet or exceed UL 94V0, Docket 90, FDA, 746C, and outdoor weatherable requirements.

- Fully Recyclable Material

Pressure Forming Projects