The Foundation

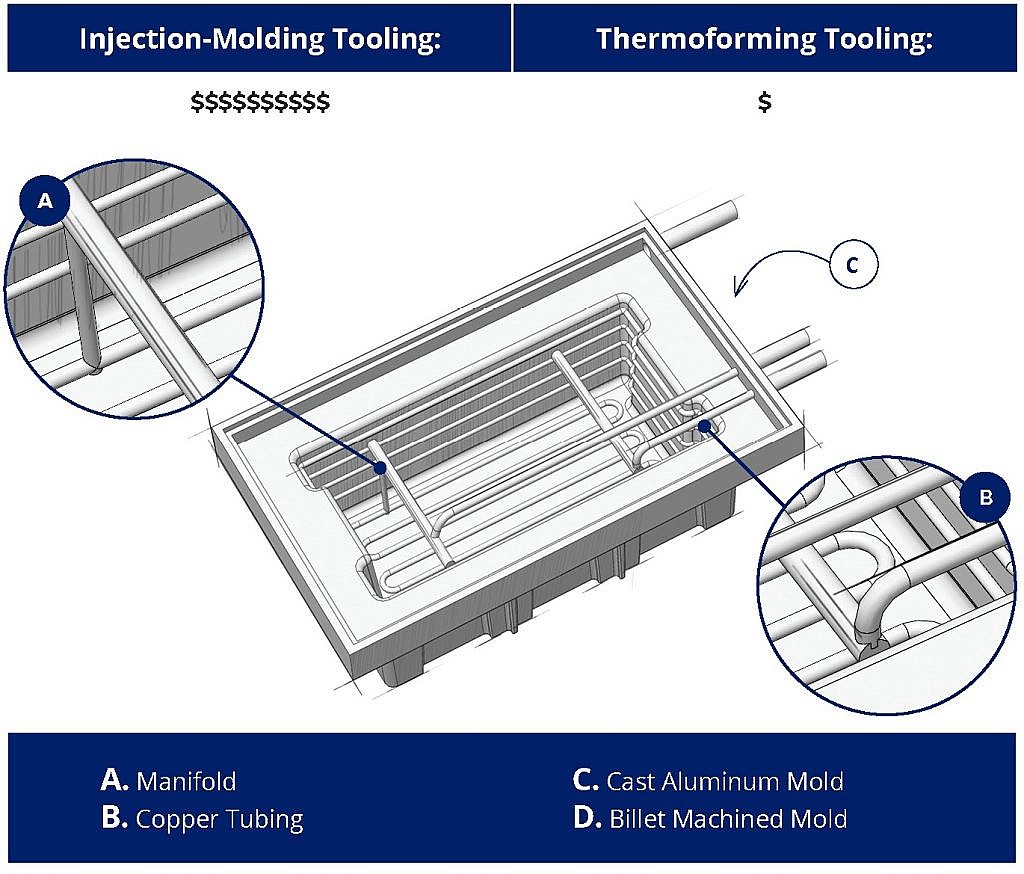

Tooling is simply the industry term for creating the mold used in thermoforming. Unlike injection molding, thermoforming uses a single-sided mold (male or female), resulting in significant cost savings.

Want the Best? Choose Aluminum, Temperature-Controlled Tooling

Thermoforming can use several different types of prototype tooling, including wood or even foam tooling. At Ray Products, we use exclusively aluminum, temperature-controlled tooling for production quantities. Non-production or bridge tooling can be discussed.

- Aluminum tooling allows for more precise, repeatable results than any other material.

- Liquid cooling allows for faster and more consistent production time.

- Aluminum tooling allows for running engineered resins and materials with a very tight processing window.

SEE BLOG INFO: www.rayplastics.com/news

Ray Products Thermoforming Tooling

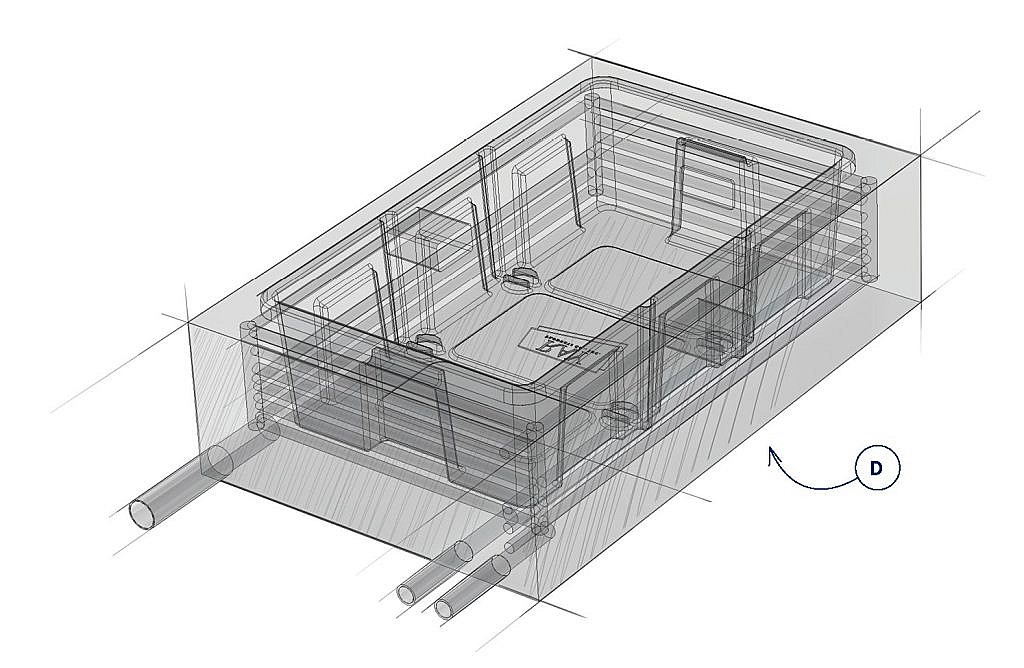

- Billet-Machined or Cast Aluminum

- Guaranteed For Life

- Pressure Forming Up to 6 feet x 10 feet

- Vacuum Forming Up to 10 feet x 18 feet

- Up to 90% Savings Over Injection Molding Tooling

- Temperature-Controlled Tooling

- Gun-Drilled Cooling Channels

- Automated Tooling with Actuating Slides for Undercuts and Features

Temperature-Controlled Tooling

It’s important that during the pressure-forming process, the tooling maintains a consistent temperature. Without cooling, the tool would heat up during the pressure-forming process, as it comes into contact with more and more sheets of heated plastic. This would require waiting for the tool to cool between the molding of each part and significantly slow the manufacturing process.

Our liquid cooling system circulates fluid through the tool during the pressure-forming process, drawing heat away from the mold and allowing the production run to move rapidly while maintaining the quality of the thermoformed parts.

The cooling channels are created during the tooling manufacture process, using a precision drilling technique called “gun drilling, “which was originally developed for (you guessed it) drilling out the barrels of precision firearms.