It’s that time of year, again. MD&M – the nation’s largest medical device industry tradeshow – is hosting its West Coast conference in Anaheim, CA, and Ray Products is thrilled to be returning to the floor as an exhibitor. The showcase provides an excellent opportunity for our company to connect with hundreds of engineers, innovators, designers, and large-scale medical device corporations and share the full range of manufacturing solutions our pressure forming and vacuum forming capabilities can provide. We’ve met many of our long-term clients at previous MD&M showcases, and it’s always exciting and inspiring to not only learn of the cutting-edge innovations emerging within the medtech industry but to also be a part of their creation.

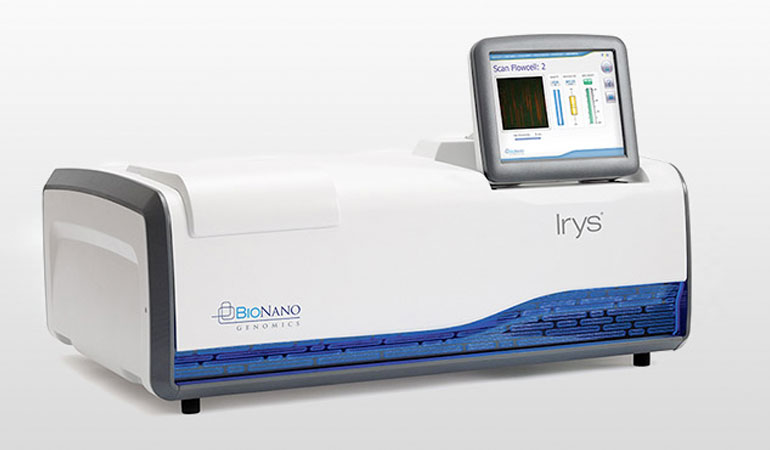

Medical devices have always comprised a significant portion of Ray Products’ manufacturing projects. In fact, the plastic product that put our company on the map over 70 years ago was a medical device: one of the earliest clear plastic baby bassinets on the market. Since then, we’ve thermoformed plastic parts and enclosures for countless instruments used in the field of healthcare, including this cancer diagnostic machine, this DNA sequencer, this hospital cart, and many others.